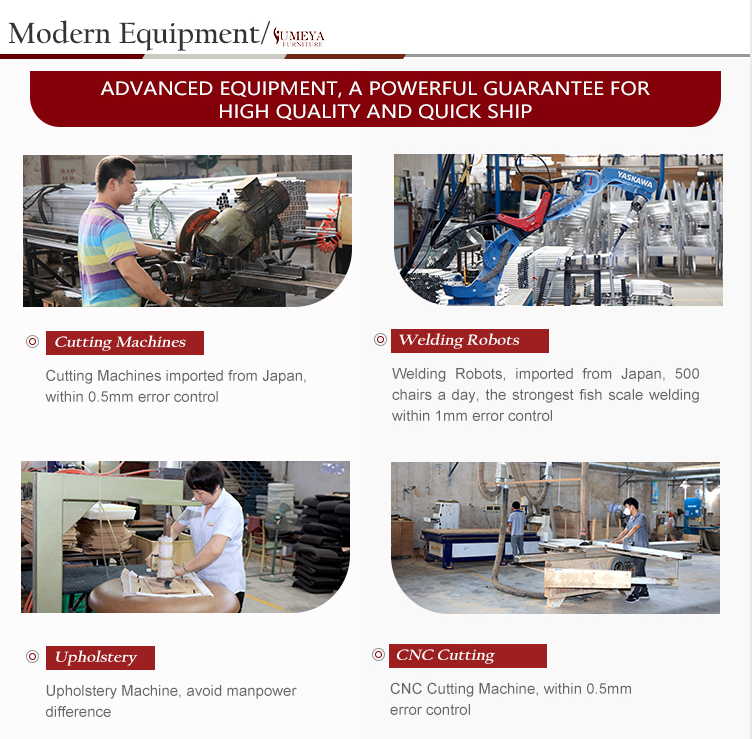

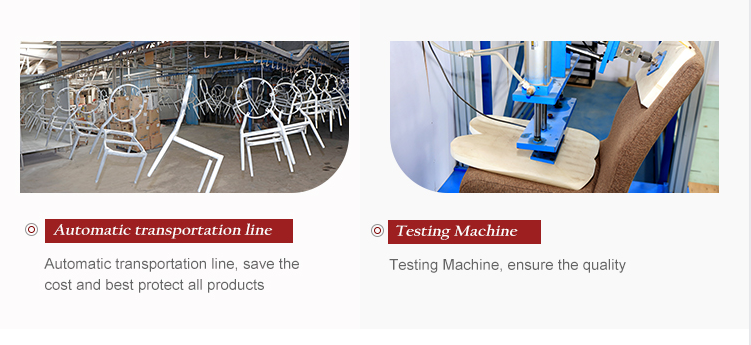

Doing surface treatment in a chair, similar to make-up, first of all must have a smooth frame. All Yumeya chairs need to go through four polishing processes before they can formally enter the surface treatment process.

Fine polishing, the first step to get perfect wood grain in a metal chair.

Doing surface treatment in a chair, similar to make-up, first of all must have a smooth frame. All Yumeya chairs need to go through four polishing processes before they can formally enter the surface treatment process.

1. Component polishing

After welding, many corner positions cannot be polished. Therefore, each part and each tubing must be polished before welding to make sure the surface is smooth.

2. Polishing after welding

In this process, we will polish the weld part, to make it seem like a mold made product, and you can not see any weld mark.

3. Fine polish for the whole chair, to make sue the whloe frame is smooth and no scratches.

4. Polishing after cleaning, to remove small scratches after cleaning

After 4 steps, it can achieve good flat and smooth effect.

For most people, they will know that there are solid wood chairs and metal chairs, but when it comes to metal wood grain chairs, they may not know what product this is. Metal wood grain mean to do wood grain finish on the surface of metal. So people can get a wood look in a metal chair.

Since 1998, Mr. Gong, founder of Yumeya Furniture, has been developing wood grain chairs instead of wood chairs. As the first person to apply wood grain technology to metal chairs, Mr. Gong and his team have been working tirelessly on innovation of wood grain technology for more than 20 years. In 2017, Yumeya start the cooperation with Tiger powder, a global powder giant, to make the wood grain more clearer and wear-resistant. In 2018, Yumeya launched the world's first 3D wood grain chair. Since then, people can get the look and touch of wood in a metal chair.

There are three incomparable advantages of Yumeya metal wood grain technology.

1)No joint and no gap

The joints between pipes can be covered with clear wood grain, without too large seams or no covered wood grain.

2)Clear

All surfaces of the whole furniture are covered with clear and natural wood grain, and the problem of fuzzy and unclear texture will not appear.

3)Durable

Cooperate with world famous powder coat brand Tiger. Yumeya’s wood grain can be 5 times durable than similar products in the market.

As solid wood chairs will be loose and cracked due to the change of environment moisture and temperature. High after-sales cost and short service life have increased the overall operating cost. But it has less impact for metal wood grain chair as it is connected by welding. So now more and more commercial place will use meal wood grain chairs instead of solid wood chairs to reduce the cost and accelerate the return on investment. As a new product in the market, Yumeya Metal Wood Grain Seating combines the advantages of metal chairs and solid wood chairs.

1) Have solid wood texture

2) High strength, can bear more than 500 lbs. Meanwhile, Yumeya provide 10 years frame warranty.

3) Cost effective, same quality level, 70-80% cheaper than solid wood chairs

4) Stack-able, 5-10 pcs, save 50-70% transfer and storage cost

5) Lightweight, 50% lightweight than same quality level solid wood chairs

6) Environmentally friendly and recyclable

Why Choose Yumeya?